Mattress Buying Guide for Exporters: Detailed Comparison of Roll Packed, Memory Foam, Pocket Spring, Hybrid, and Latex Models

Why Technical Details Matter in Mattress Selection

For B2B buyers, mattress selection isn’t just about comfort — it’s a supply chain and product lifetime decision.

Each mattress type offers distinct benefits in cost, logistics, and durability. Understanding the materials, compression method, and density parameters helps reduce returns, improve logistics performance, and match regional customer expectations.

This guide outlines the seven most common mattress types, including technical parameters, target users, and export recommendations.

Roll Packed Mattress — Space-Saving Logistics Champion

Core Structure:

-

Comfort Layer: 2–4 cm high-resilience foam (HR ≥ 35 kg/m³)

-

Support Layer: PU foam or pocket coil core

-

Base Layer: 2 cm supportive PU or latex sheet

-

Cover: Knitted fabric (polyester/spandex blend), 300–400 g/m²

Compression & Packaging:

-

Volume reduction: up to 70–75%

-

Box size: 100×40×40 cm (Queen), 120×45×45 cm (King)

-

Recovery time: 24–48 hours after unboxing

-

Suitable for: container shipping, e-commerce logistics, furniture retail

Why It Works:

Roll packed mattresses maximize container efficiency (up to 3× more units per load) and cut freight costs by 50–60%.

They’re ideal for OEM/ODM exporters who need lightweight packaging and low-damage transport.

Buyer Tip:

If your main market includes e-commerce, rentals, or hotel chains, prioritize models with automated compression systems and 5-layer PE film sealing to ensure consistent vacuum integrity.

Memory Foam Mattress — Personalized Pressure Relief

Core Specs:

-

Material: Viscoelastic polyurethane foam

-

Density: 45–65 kg/m³ (medium firmness range)

-

Thickness: 20–30 cm (customizable)

-

Thermal Conductivity: 0.04–0.06 W/m·K (low heat transfer)

-

Lifespan: 8–10 years under normal usage

Performance Highlights:

-

Adapts to body temperature and contour

-

Reduces spinal pressure and joint fatigue

-

Motion isolation for shared beds

-

Low noise, zero metal component design

Recommended Users:

Home furniture brands, healthcare institutions, and rental projects focusing on ergonomic comfort.

Buyer Tip:

For export to tropical or humid climates, select open-cell memory foam or gel-infused models for better temperature regulation.

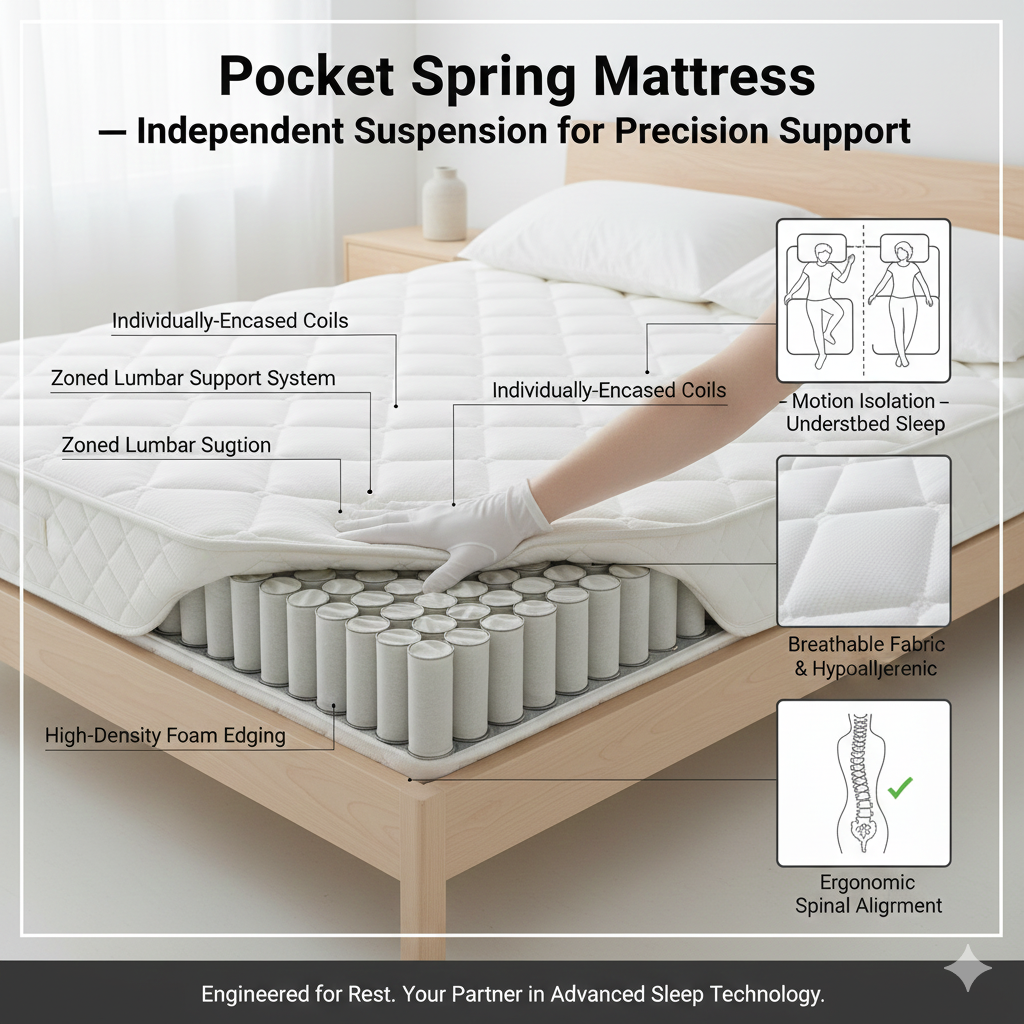

Pocket Spring Mattress — Independent Suspension for Precision Support

Construction:

-

Coil count: 800–1000 per 1.5×2.0 m mattress

-

Coil diameter: 5–6.5 cm

-

Wire gauge: 1.8–2.2 mm (tempered high-carbon steel)

-

Insulation: Non-woven fabric pockets

-

Comfort layer: 3–6 cm foam, latex, or fiberfill

Advantages:

-

Each spring reacts independently — zero motion transfer

-

Reinforced perimeter support prevents sagging

-

Excellent ventilation — ideal for warm environments

-

Firmness can be zoned (soft/medium/firm areas)

Quality Indicators:

Compression resilience ≥ 95% after 50,000 cycles

Spring fatigue loss ≤ 3% after 10 years

Buyer Tip:

If targeting premium markets or hotel projects, choose models with multi-zone spring layouts and OEKO-TEX certified covers for enhanced durability and compliance.

Hybrid Foam Mattress — Balanced Comfort Meets Longevity

Layer Structure Example (Queen Size 25 cm Thick):

-

Cooling knit cover (400 g/m² breathable fabric)

-

4 cm gel memory foam

-

8 cm individually wrapped pocket springs

-

10 cm high-density support foam (≥ 38 kg/m³)

-

Anti-slip bottom fabric

Performance:

-

Balanced body alignment and bounce

-

Superior airflow for temperature control

-

Retains 98% height after long-term compression testing

Logistics:

Can be roll-packed; maintains consistent structure after vacuum compression.

Buyer Tip:

Choose hybrid models when targeting multi-climate or mixed user demographics — they perform well in both cold and hot regions, appealing to mid- to high-end export markets.

Bed-in-a-Box Mattress — Simplified Retail & Last-Mile Delivery

Key Specs:

-

Standard box size: 100×40×40 cm

-

Vacuum-sealed and rolled; expands fully in 24h

-

Weight range: 25–45 kg (Queen size)

-

Ideal thickness: 20–25 cm

Benefits:

-

Perfect for online direct-to-consumer (DTC) sales

-

Easy warehouse stacking and minimal damage risk

-

Enables branding — custom boxes, color-printed sleeves, and QR-coded packaging

Buyer Tip:

Choose eco-friendly packaging (PE + EVA film) and certified compression equipment to align with sustainable e-commerce logistics standards.

High Density Mattress — Industrial-Grade Durability

Material Profile:

-

Core: Polyurethane or rebonded foam

-

Density: 35–50 kg/m³

-

Firmness: Medium to firm (ILD 40–60)

-

Compression deformation: <5% after 10,000 cycles

Applications:

Hotels, dormitories, hospitals, military and staff accommodation.

Benefits:

-

Low deformation rate and extended service life

-

Good for repetitive short-term usage

-

Compatible with compression packing

Buyer Tip:

If durability outweighs plush comfort in your market (e.g., hospitality or government contracts), high-density foam is a cost-efficient, long-lifespan solution.

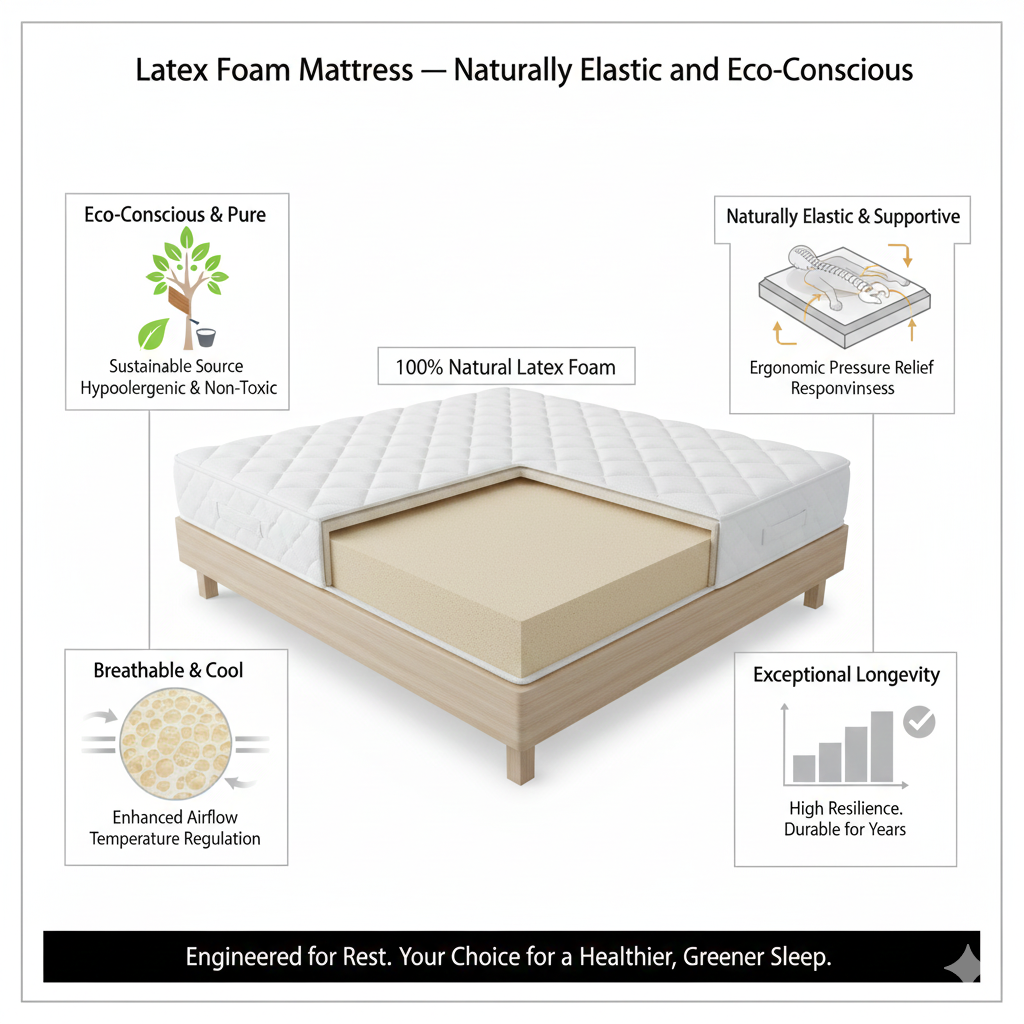

Latex Foam Mattress — Naturally Elastic and Eco-Conscious

Technical Specs:

-

Material: 100% natural latex or blended latex

-

Density: 60–85 kg/m³

-

Firmness: ILD 25–40 (soft to medium)

-

Elastic Recovery: >99%

-

Ventilation: Open-cell honeycomb structure

Unique Benefits:

-

Naturally hypoallergenic and antibacterial

-

Excellent breathability and rebound rate

-

Suitable for tropical climates and luxury exports

Buyer Tip:

Opt for Talalay latex for superior softness or Dunlop latex for denser, firmer models. Always request REACH / SGS certificates for EU market compliance.

Comparison Table — Quick Technical Overview

| Type | Density (kg/m³) | Compressible | Lifespan | Ideal Market | Key Advantage |

|---|---|---|---|---|---|

| Roll Packed | 35–40 | Yes | 8–10 yrs | E-commerce / Export | Space-saving logistics |

| Memory Foam | 45–65 | Partial | 8–10 yrs | Residential / Health | Adaptive comfort |

| Pocket Spring | — | Limited | 10+ yrs | Hospitality / Premium | Independent coil support |

| Hybrid Foam | 35–60 | Yes | 10+ yrs | Global Retail | Balanced performance |

| Bed-in-a-Box | 35–45 | Yes | 8–10 yrs | Online / DTC | Compact delivery |

| High Density | 40–50 | Yes | 10+ yrs | Commercial / Institutional | Extreme durability |

| Latex Foam | 60–85 | No | 12+ yrs | Premium / Eco Market | Natural elasticity |

How to Choose the Right Mattress for Your Market

-

Consider Climate:

-

Hot & humid → Latex or Hybrid

-

Cold & dry → Memory Foam or Pocket Spring

-

-

Logistics Model:

-

Cross-border export → Roll Packed / Bed-in-a-Box

-

Local retail → Pocket Spring / Hybrid

-

-

Target Price Segment:

-

Budget → High Density or Roll Packed

-

Mid-range → Memory Foam or Hybrid

-

Premium → Latex or Zoned Pocket Spring

-

-

End-User Type:

-

Hotels → Pocket Spring / High Density

-

Online Sales → Roll Packed / Bed-in-a-Box

-

Institutional → High Density Foam

-

FAQ

Q1. Can all types be roll packed?

No. Latex mattresses have limited compressibility, while hybrid and pocket spring models require specialized vacuum lines.

Q2. What certifications should exporters request?

CertiPUR-US, OEKO-TEX, REACH, and ISO 9001 for material and production compliance.

Q3. How long can a compressed mattress be stored?

Typically 6 months, provided temperature remains under 25°C.

Final Takeaway

Modern mattress technologies are not competing — they’re complementary.

By matching compression capability, material density, and target market you can build a product portfolio that maximizes logistics efficiency while meeting diverse comfort preferences worldwide.

To explore OEM or private label cooperation for export-ready mattress lines, visit Homezeno Homepage or Contact Us.